This blog series is a review of the specifications and design methodology required to create compute platforms that can be deployed into Edge Telecom Environments.

The goal of GR-63-CORE, Physical Protections, is to increase network availability and lower the overall costs of installation and maintenance of network equipment. It primarily addresses thermal, humidity and altitude levels, transportation and storage, seismic activity and vibration, flame resistance, air filtration and noise.

There are other criteria associated with physical design, describing dimensions, weight, cable management, mounting options, among others. But these are static measurements that are performed without any additional testing.

In addition, the packaging of the device is also tested to verify that the packaging can withstand the typical physical shock and drops that may be encountered in shipping.

Thermal, Humidity and Altitude

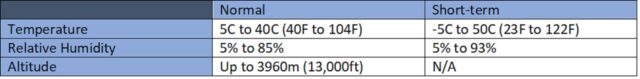

These requirements and tests provide the operational ranges, both normal and short term, where the networking equipment must operate. For NEB Level 3, the temperature and humidity requirements are:

Total test time, for different combinations of temperature and humidity, takes place over a contiguous six day period. Pass/Fail for these tests, running an active processing load, is a fully functional device with no observable damage or reduction in performance.

Transportation and Storage

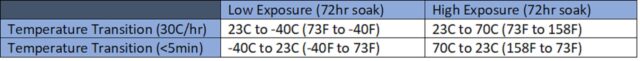

These tests attempt to simulate the extremes of shipping equipment for storage or installation, assuming some extreme ranges of temperature and humidity, accompanied by rapid changes in temperature, or thermal shock. This could, for example, simulate equipment leaving a temperature-controlled warehouse in Minneapolis, in January, or Phoenix, in July. In both cases, the equipment could transition from a relatively comfortable environment to that of extreme cold or heat in a short period of time.

Similar tests are performed for rapid humidity shifts, from a base 50 percent to 93% RH over a 23°C (73°F) to 40°C (104°F) temperature range and set rate changes and durations. Again, these simulate the environmental challenges found in shipping electronic equipment from factory/warehouse to installation.

Pass/Fail for these tests is a fully functional device once the unit is returned to the operational temperature/humidity range and powered up.

For these first two categories, testing is typically performed in a Highly Accelerated Life Test (HALT) chamber. This chamber allows for testing in a range of temperature, humidity and barometric pressure (altitude). Its purpose is to speed the discovery of latent defects in manufacturing during the production stages of a product life cycle to reduce associated failures, or more simply put, discovering potential weak links of a product.

Seismic and Vibration

Seismic testing tests the device on a shake table, subjected a simulated earthquake in the X, Y and Z axes. NEBS Seismic Zone 4 certification, which is required in many regions, is the equivalent of an 8.3 magnitude quake.

For installations in a rack or enclosure, deformation is measured and a “sway” beyond a certain level will fail the test. Physical damage to the rack and enclosed hardware is also evaluated. These tests are performed with operating compute/storage/networking unit running a test load. Resets or any failures of the operating hardware under test would also constitute a failure of the seismic test.

In a previous life, I was involved with a Seismic Zone 4 Test on a full rack of equipment. The first iteration of the test failed, as the rack started to experience a rapid unplanned disassembly. While failing this test, it was also a learning experience as failure points, metal fatigue, compromised welds and deformations were analyzed, the rack design improved and the next test, a few months later, passed with flying colors.

Flame Resistance

Resistance to fire and the ability to self-extinguish are critical factors in NEBS Testing. Throughout the history of the telecommunications industry, there have been multiple, high-profile outages that can be attributed to fire or smoke. None are more famous than the 1975 New York Telephone Exchange Fire, which was the most significant service outage of the 20th century and is still studied to this day in terms of causes, response and the heroic efforts to re-establish service from this outage.

Equipment under testing is exposed to both high temperature burners and direct flame exposure. While the equipment may catch fire when directly exposed to an extreme heat source, the criteria are that the fire does not spread beyond the unit and the fire self-extinguishes and ceases smoking within a set interval of time. Of course, this is a destructive test and no functional requirement remains after completing these tests.

Air Filtration

As implied by the previous tests, telecom equipment is often deployed in less-than-ideal conditions. Besides temperature, humidity and seismic extremes, the device is often exposed to airborne contaminants, which can be in the form of dust or corrosive gases. Providing proof of protection against airborne contaminants is required to ensure the device meets its intended service life. For servers, a filtered bezel can be utilized at the air inlet to prevent dust intrusion.

Noise

To ensure a safe working environment, acoustic noise for the operating device under test is also measured. Normal operating noise levels, at room temperature, are taken and must not exceed fixed values. These values can differ, depending on if the equipment is deployed in a Telecommunications Room (78dB) or a Power Room (83dB). The maximum acoustic noise level, with fans spin rates at maximum RPMs, is also measured, but there is no pass fail for extreme operating, assumed temporary, conditions.

Conclusion

GR-63-Core addresses the physical requirements of an electronic device deployed in a telecommunications environment. Its intent is both to guarantee the device’s operability under extreme conditions and the safety of its surroundings and operators.

Please follow updates on our Dell Edge and Telecom Twitter account and explore more insights on our Telecom solutions site.