Dell Pro Max

Wade Trim Accelerates Material Design and Simulation

Key takeaways: Wade Trim’s fluid‑dynamics engineers were constrained by slow, unpredictable simulations that forced approximations and limited exploration. After adopting Dell Pro Max workstations with NVIDIA RTX PRO GPUs, simulation times dropped from 27–48 hours to 8 hours. Server-class performance also unlocked higher‑resolution modeling, more design iterations, and allowed distributed teams to access from anywhere.

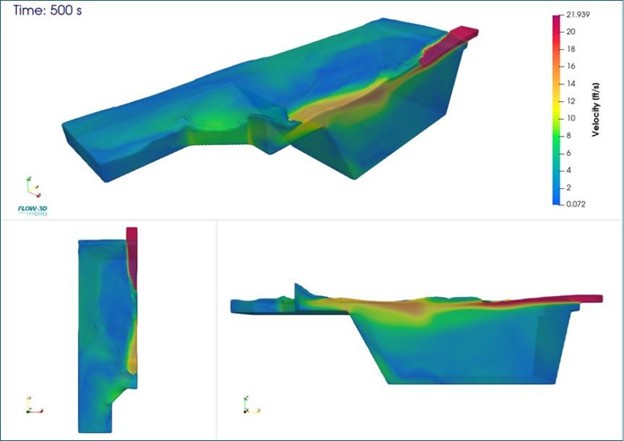

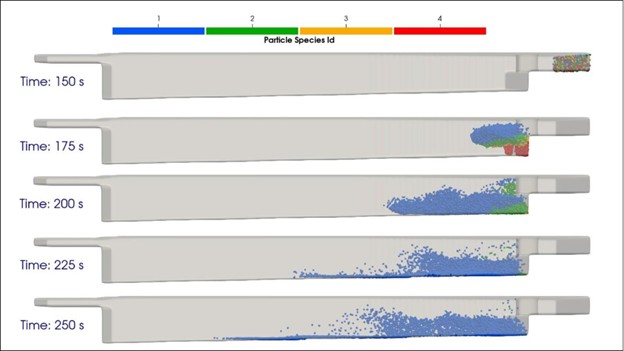

Over the past century, Wade Trim has helped solve infrastructure problems for clients across the country. Engineers work on various private and public works projects, including transportation, stormwater management, and wastewater treatment. Their work involves computationally intensive simulations of particles and fluid dynamics.

Simulating models of real-world structures validates engineering specs and can identify issues and improvements before material design begins. Working on standard computers in their industry, high-fidelity simulations built with software such as FLOW-3D required between 27 and 48 hours to complete. To meet deadlines, engineers relied on approximations. They would reduce resolution or the number of time steps captured in the simulation. The engineers felt constrained, and the simulations didn’t show as much accuracy as they desired, but the results were usable, even if the simulation times remained unpredictable.

Approximating by necessity

Ross Volkwein is a lead modeler at Wade Trim. He described the trade-offs the hydraulics team made to keep simulations manageable: “Instead of running real-time simulations, we were forced to decrease the number of time steps and the temporal resolution. We would approximate by necessity.”

Constraints on time and available compute only allowed for simulations that smoothed over the details. Results demonstrated the general behavior of a system, but fluid dynamics at full resolution would have revealed information that the compressed models could obscure.

Unreliable timelines

Runtime variability created a second problem. A simulation that took 27 hours one day might take longer after a parameter change. Engineers could not plan around the unpredictability.

“It’s a big difference kicking off a run and not being sure when it’s going to finish and how that feeds into the rest of your workday or work week,” Volkwein says. “If this model is going to take 48 hours, maybe it takes longer than that after a change you make and then all of a sudden your schedule is under pressure.”

Engineers adapted by building buffer time into schedules and avoided changes that might extend runtimes. Uncertainty shaped how they worked.

Constrained experimentation

Long runtimes limit how many alternatives an engineer can explore. If each iteration is a multi-day commitment, then running five design variations becomes a week or more of compute time. This results in conservative experimentation. Engineers run fewer alternatives and accept results earlier than they might prefer.

Breaking constraints in high fidelity

When the fluid dynamics team tested a Dell Pro Max workstation configured with the NVIDIA RTX PRO 6000 Blackwell Workstation Edition GPU, the performance gains from running the simulations natively on the GPU transformed their process. In one case, a grit chamber simulation time dropped from 12 hours and 15 minutes to just under 5 hours. Hydraulic structure models that previously ran for days finished in eight hours. An eight-hour runtime means an engineer can reliably initiate the process at the end of their day and return to review the results in the morning.

The colleague who had reduced his simulation detail to fit within a practical runtime reviewed the new benchmarks and realized the Dell Pro Max workstation could now run the full time series in a single day. “That’s a big change in practicality,” Volkwein shared.

More iterations, better outcomes

Faster completion times allow engineers to run more design alternatives within the same project schedule. “Being able to run more alternatives is obviously conducive for us to explore a greater number of options, which is a benefit to our clients,” Volkwein says. “We’re using the latest and greatest technology to make sure that we’re rapidly iterating and not just taking a shot in the dark, getting the results and calling it quits.” Questions that previously went unasked because simulation times couldn’t justify them, now get answered.

Strategic investment

Wade Trim is already planning to expand their usage of Pro Max workstations. These workstations can be effectively shared across teams. “I can see us putting at least one of these in strategic locations across our footprint for our engineers to use,” says Rob Sinclair, who oversees technology at Wade Trim. “Maybe five machines right off the bat, then expanding to roughly ten in the near future.”

The first workstation, currently in Pittsburgh, is expected to be in high demand. Engineers across regions will remote in for compute-heavy tasks, turning the Pro Max into a shared center of excellence. “I can see this machine being in high demand once we release the floodgates.”

Ready to transform your engineering workflows?

If your team is still approximating because compute holds you back, it’s time to rethink what’s possible. Explore what Dell Pro Max workstations with NVIDIA RTX PRO GPUs can unlock for your simulations, modeling, and high‑fidelity workflows. Let’s accelerate your engineering accuracy, creativity, and impact together. Learn more about Dell Pro Max solutions.