Manufacturers are increasingly investing in edge innovation to drive smart manufacturing. Numerous advanced edge applications, such as digital twin and computer vision, are transforming continuous, real-time streaming data – from people, equipment, facilities and products – into insightful innovation, more efficient operations and revenue growth.

But barriers to edge success are significant. Data silos, scalability limitations, fragmented technologies and security concerns are but a few of the obstacles holding back the full potential of computing at the edge. Manufacturers are also burdened by the complexity of figuring out the optimal architecture that will scale these applications in the future.

A recent Vanson Bourne research study of more than 1,800 large enterprises globally showed that while 94% of organizations intend to deploy edge solutions, only 10% report being in advanced production. The study also shows that approximately 85% report they need a simpler approach to edge set-up. While organizations understand the benefits of edge computing solutions, implementation and complexity are holding them back.

These challenges are limiting edge investment ROI, which slows the adoption of smart manufacturing initiatives and limits their benefits. To overcome this, enterprises need to take a comprehensive approach to edge deployments.

Dell Validated Design for Manufacturing Edge

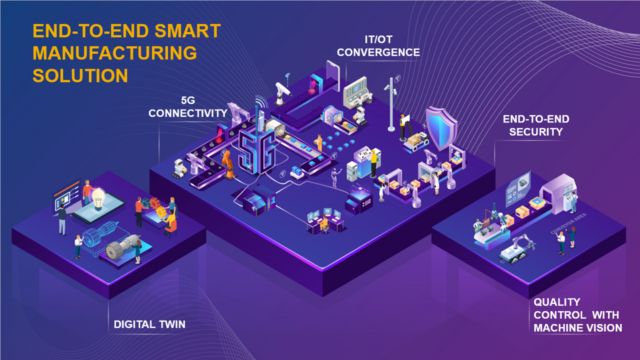

Dell Technologies helps manufacturers succeed at the edge. We develop edge computing solutions that specifically target the challenges and opportunities faced by manufacturers when it comes to the edge. The Dell Validated Design for Manufacturing Edge is an engineered solution that enables transformative outcomes in manufacturing by:

-

- Delivering IT and OT convergence

- Providing a modern technology architecture for running diverse applications

- Breaking down silos of technology across the factory

- Ensuring greater security and control at the edge

- Establishing a foundation for future edge innovation

These validated designs provide manufacturers with a ready, end-to-end architecture that brings together all the critical edge technology components in the optimal configurations. These designs are sized based on the factory workloads and tested by the experts at Dell Technologies to enable various use cases at the manufacturing edge. This speeds edge deployment by removing much of the configuration guesswork and complexity manufacturers face when attempting to deploy edge applications.

We’re excited to announce the latest edition of these validated designs for the manufacturing edge launching on today. In this edition, we’ve focused on accelerating the adoption of advanced edge applications that power smart manufacturing initiatives.

This new solution uses an award-winning hyperconverged infrastructure – Dell VxRail – or the edge-hardened Dell PowerEdge Servers with the Dell Edge Gateways. It also includes the Dell Streaming Data Platform (SDP) for high-speed ingestion of streaming data from across data sources so data can be integrated across diverse edge applications for real-time analysis.

Dell SDP provides long-term storage and complements the Telit deviceWISE® IoT platform by enabling high-speed ingestion of IoT data for advanced analytics. SDP pulls together raw data and metadata streams, placing them in one location for comprehensive data analysis. SDP does this by storing, ingesting, and analyzing all the data as a byte-stream, so it’s in a single “common language” and can be shared across all ISV applications that are integrated into the solution.

These edge-optimized technologies enable a scalable unified technology architecture validated to run advanced edge applications like digital twins, machine vision and others from four leading application vendors.

-

- Cognex is a global leader in machine vision and industrial barcode reading solutions. They help customers improve manufacturing quality and performance by identifying defects, verifying assembly and tracking information at every stage of the production process.

- Claroty is a leading industrial cybersecurity company that helps extend core IT security controls into industrial environments.

- Telit Cinterion is a market leader and innovator for industrial IoT solutions. They offer products and services for companies – large and small – that rely on mission-critical connectivity, security, scalability and enterprise-grade performance.

- XMPro is an application composition platform to build the digital twins of factory operations. Its no-code digital twin composition platform accelerates operational and situational awareness for factory operators.

Together, these vendors allow us to deliver remarkable outcomes for manufacturers, including:

-

- 450+ extended IoT protocol coverage by Claroty for visibility and security of cyber-physical systems

- More than 400 vulnerabilities disclosed by Claroty’s award-winning industrial cybersecurity research team

- 184 hours of preventable downtime identified using XMPro’s application platform for creating digital twin of a factory facilities

Solutions with Speed, Scalability and Resiliency to Drive Smart Manufacturing Outcomes

The latest edition of the Dell Validated Design for Manufacturing Edge helps manufacturers overcome the most common edge challenges and gain business advantage around improving efficiencies, reducing wastes, and growing revenue by:

-

- Unifying IT and OT, seamlessly by eliminating data silos from edge devices on the factory floor to enterprise applications in the cloud, for faster time to value

- Streamlining digital transformation use cases with easy and quick deployment of innovative technologies for operational agility and improved production quality

- Scaling securely using proven solutions that protect the edge estate, from IT to OT

To learn more about our validated designs for the manufacturing edge, please click here.